Kipp Umwelttechnik cleans fin heat exchanger, plate heat exchanger, tube bundle heat exchanger with special process from mycon

Development of cost-effective systems makes fully automated cleaning systems economic feasible

With the JetMaster system from mycon GmbH, fin heat exchangers of any type can be cleaned by high-speed / cavitation effect. Only 0.20-075 liters of water is used per minute. As a result, the use of the method is also possible in a moisture-sensitive environment. The complete system JetMaster+ offers four different combination options, which can be matched exactly to the cleaning task.

JetMaster

A critical issue is always the cleaning of finned heat exchangers in the interior of food production or food storage, so it is sometimes postponed as long as possible. Even in these areas, JetMaster offers the possibility of cleaning heavily loaded finned heat exchangers without removal. Here special nozzles are used. The extremely small amount of water of less than 0.50 liters per minute required for cleaning can be collected together with the cleaning residues for disposal.

Finned heat exchanger of a dairy, left before and right after cleaning

Heat exchanger in meat production before and after cleaning

Heat exchangers used in the storage area of food at the top Exterior view, bottom left before cleaning, bottom right after cleaning

Cleaning of inaccessible or non-removable plate and tube bundle heat exchangers

Also not accessible, or removable plate and tube bundle heat exchangers can be cleaned. For this purpose, a rinsing process developed by mycon GmbH is used. Preferably “green” chemistry, which is partly used in the food industry, delivers convincing cleaning results.

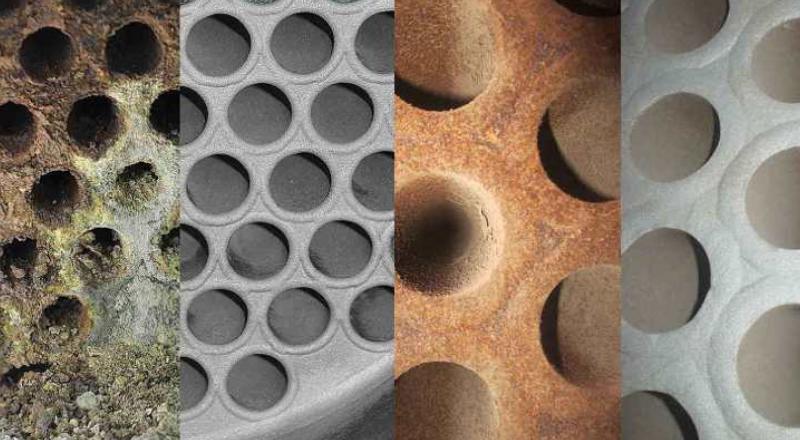

Non-removable plate heat exchanger and closed tube bundle heat exchanger

Cleaning of tube bundle heat exchangers with the TubeMaster system

Even heavily soiled tube bundle heat exchangers can be cleaned with the help of the TubeMaster system. For this purpose, either dry ice or granules can be used as a blasting agent. In addition, it is possible to polish the inner tube surfaces with the same process. TubeMaster can be used both manually and automatically. Both variants are also offered by mycon GmbH for rent and for sale. Also with a rented plant a purchase is possible at any time. The service is carried out throughout Germany by Kipp Umwelttechnik, sister company of mycon GmbH. In Switzerland, the service is provided by Puraclean GmbH, a subsidiary of mycon GmbH.

Tube bundle heat exchanger before and after cleaning with the TubeMaster system

Cleaning of removable plate heat exchangers with the PowerMaster system

Removable plate heat exchangers can be cleaned quickly and gently with the aid of the PowerMaster system from mycon GmbH. The PowerMaster blasting system works with small amounts of water (0.5 to 1l per minute) and compressed air (2 to 8 bar). PowerMaster comes with a variety of nozzle types and nozzle sizes, allowing it to adapt to virtually any requirement.

Cleaning removable plate heat exchanger, left before and right after cleaning

Cold store cleaning process – safety through certification

Kipp Umwelttechnik not only carries out the cleaning of heat exchangers, but also the cleaning of cold stores. For this purpose, a method developed by mycon GmbH and a cleaner also developed by mycon GmbH are used. Processes and cleaners have been officially tested and certified by the company Wessling, Hanover. As an accredited laboratory, Wessling stands for excellent quality of high-grade laboratory analysis and engineering consulting services.

Both food compatibility and safety are ensured by the certification including the operating instructions of mycon. When commissioned by Kipp Umwelttechnik GmbH, a safe and food-law-compliant sequence of the cleaning process is guaranteed. The process has clear advantages over other processes:

- Cold stores can stay in operation during cleaning,

- Goods can remain in the cold store during cleaning (only about 40% free space is required),

- Saving the rent of a refrigerated container,

- No relocation of goods in additional refrigerated containers, therefore no extra personnel costs,

- No interruption of the cold chain,

- Frozen temperature is maintained, therefore no further energy costs occurs for the cooling down,

- Less time (about 5 hours for 45 m²).

Photos: mycon GmbH | Kipp Umwelttechnik GmbH