Suitable Products

IceMaster

IceMaster AL

IceMaster XLM+LM

IceMaster XLC+LC

IceMaster XSP+SP

IceMaster ABC

Cleaning with dry ice

IceMaster, an effective blasting system for manual and automated dry ice cleaning and dry snow cleaning of surfaces of any kind, works only with compressed air and liquid CO2. Dry ice or dry snow particles are produced directly from the blasting gun during the blasting operation. All IceMaster systems offer residue-free cleaning, including parts cleaning, down to the dissolved dirt particles. The use of IceMaster systems is extremely environmentally friendly. The liquid CO2 used is usually recovered from industrial waste gases. It is a secondary use that does not increase the worldwide amount of CO2, with the exception of the additional CO2 quantities resulting from recovery and transport. The IceMaster system can be automated almost without limitation.

mycon offers several devices for the respective requirements.

IceMaster XSP and the automatable version IceMaster SP achieve very good cleaning power with hard particles and a massive nozzle jet for residue-free dry ice cleaning/dry snow cleaning and deburring of surfaces and parts.

IceMaster XLM and the automatable version IceMaster LM clean more gently and can be adjusted very sensitively.

IceMaster XLM and the automatable version IceMaster LM clean more gently and can be adjusted very sensitively.

IceMaster ACB can also be used for manual and automated applications for residue-free cleaning of small parts, e.g. in the electronics sector.

IceMaster AL works exclusively with liquid CO2, which forms both the propellant jet and the solid particles of dry ice/dry snow. IceMaster AL is suitable for example, for cooling and residue-free cleaning e.g. welding seams and for cleaning all soiling that can be easily dissolved by ultra-low temperatures (e.g. thin silicone adhesions).

IceMaster AL works exclusively with liquid CO2, which forms both the propellant jet and the solid particles of dry ice/dry snow. IceMaster AL is suitable for example, for cooling and residue-free cleaning e.g. welding seams and for cleaning all soiling that can be easily dissolved by ultra-low temperatures (e.g. thin silicone adhesions).

Your advantages at a glance

- Minimised operating costs

- Complete automation capability

- Constant availability

- Easy handling

- Compressed air requirement: from 450 litres/min. 2 bar

IceMaster AL Glass bottle cleaning with dry ice in the medical sector

IceMaster Dry Ice & Dry Snow Automation

IceMaster LM: Cleaning of weld seams on a high-speed train to visually check for possible cracking.

IceMaster SP: Dry ice cleaning & deburring of aluminium parts by robot

Application Examples

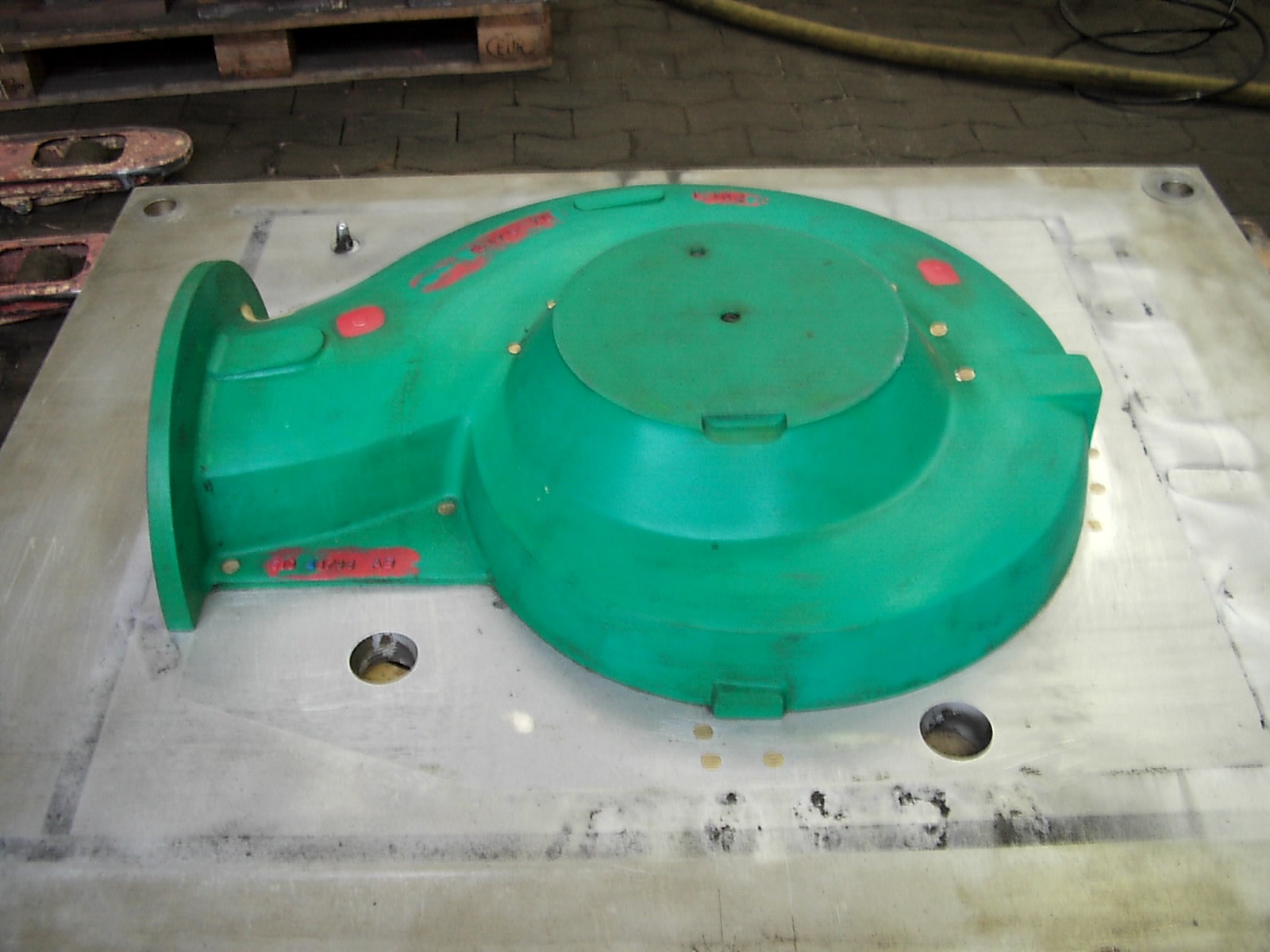

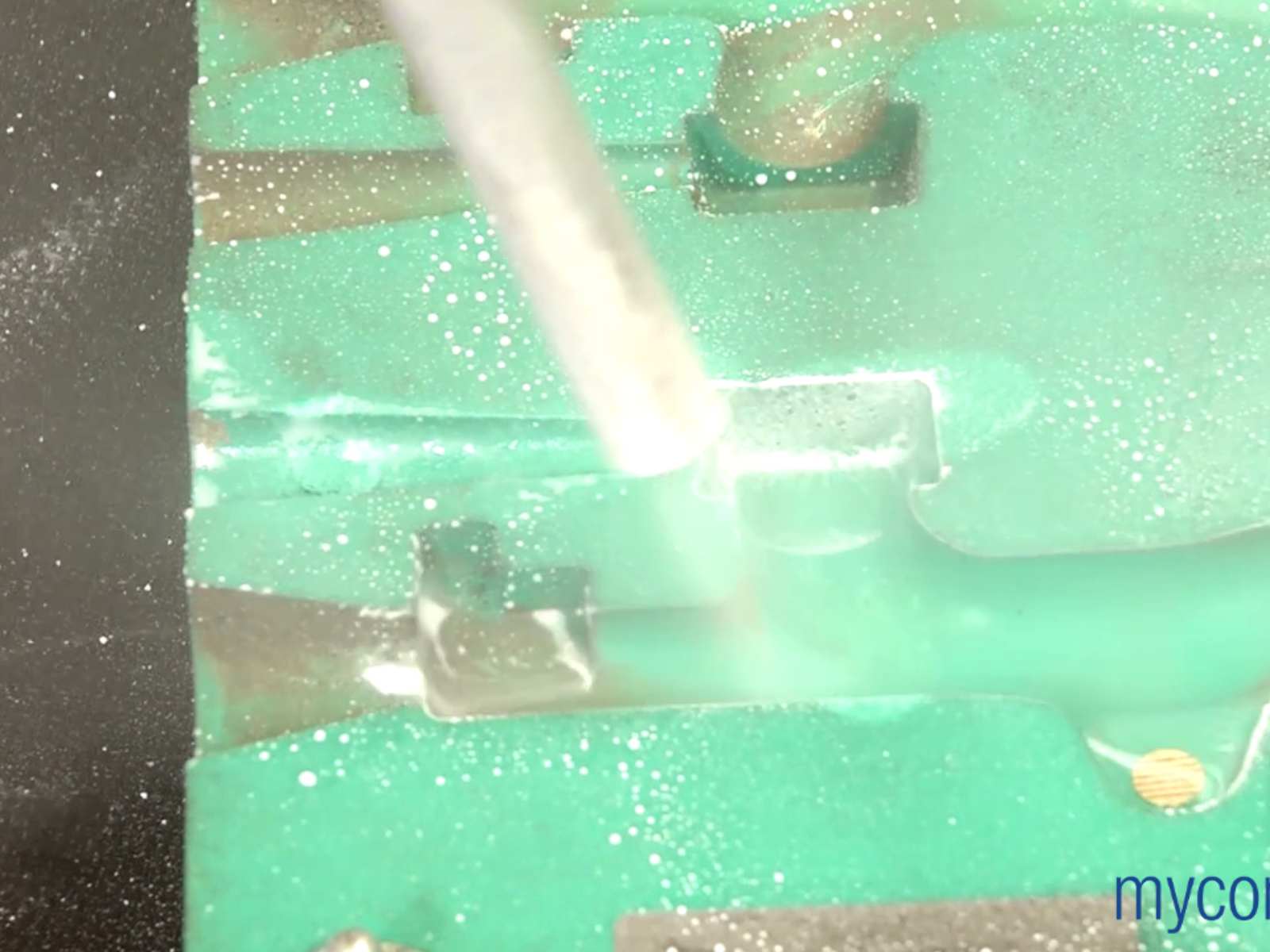

Core box cleaning - After

Core box cleaning - After Core box cleaning - Before

Core box cleaning - Before

Core box cleaning