mycon and Kipp Umwelttechnik offer efficient cleaning for rail technology

Efficient heat exchanger cleaning with JetMaster

The rail technology sector has already been using mycon GmbH’s highly-effective JetMaster cleaning system for cleaning heat exchangers under, in and on trains for many years. JetMaster makes the process of cleaning fin heat exchangers better, faster and more environmentally friendly, thus enabling significant savings in operating costs. The product works additive-free with 0.2-0.75l of water per minute. mycon now also offers automated solutions for the field.

Cleaning the heat exchanger of an air conditioning system on a local train

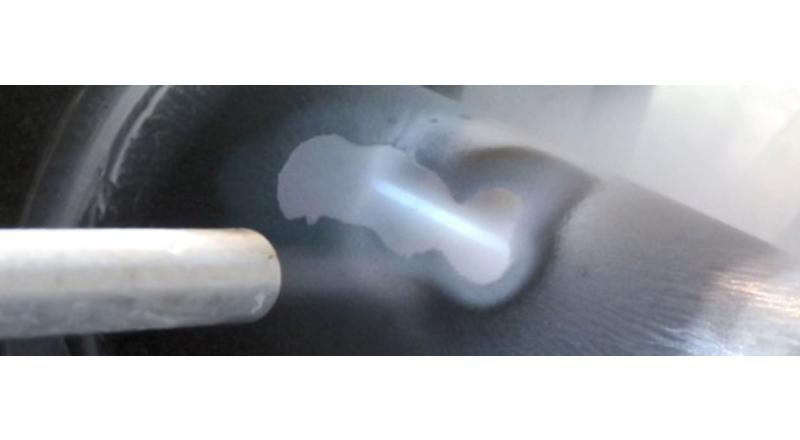

Process for cleaning and stripping axles and bogies

mycon now also offers new processes for the railway sector, such as paint stripping for axles, bogies, and other surfaces. A special system enables the cleaning and degreasing of bogies, engines, and other surfaces with approximately 1 liter of water per minute or completely water-free. The cleaning fluid used is recyclable. All processes can be applied manually or automated.

Paint removal from train axle

Cleaning bogies

Heat exchangers are used in the storage area of food at the top Exterior view, bottom left before cleaning, bottom right after cleaning

mycon devices also successful in Asia

A large rail company in Asia was also impressed by trials of mycon GmbH’s latest developments. As well as the JetMaster devices for cleaning fin heat exchangers, the trials also included new cleaning processes for manual or fully-automated stripping of axles and bogies, as well as for the water-free cleaning of bogies and other oily and greasy surfaces. There are also plans for a robot-automated under-train cleaning system using mycon GmbH’s new cleaning system. The cleaning fluid used in the planned system can be used multiple times and ultimately recycled.

Photo 1: Kipp Umwelttechnik GmbH

Photos 2+3: mycon GmbH