Digitalization in the craft trades, is that possible? The Federal Office for Economic Affairs and Export Control’s support programme for initiating energy savings with the aid of smart meters (Einsparzähler) provides the opportunity to do this.

Digitalization – turning data into useful information – makes energy production more effective and also leads to considerable energy savings.

mycon installs the first ControlMaster system for monitoring heat exchangers on the basis of algorithms as part of the BAFA-funded “Einsparzähler (smart meters)” project.

The successful cooperation between mycon and the Hamburg University of Applied Sciences (Faculty of Technology and Informatics / Prof. Dr.- Ing. Sankol) made it possible to quickly convert the data obtained into a comprehensive model calculation, which uses the mycon ControlMaster system to establish an algorithm for determining the optimum cleaning dates. ControlMaster can also activate automated cleaning processes itself, including any additional measures required. This enables considerable energy savings.

Picture: The ControlMaster of mycon GmbH

ControlMaster receives all necessary information via the corresponding sensors. Using a specially developed program, this data is used to establish an algorithm that determines the optimum cleaning date.

Customer data from the successful cooperation with Energy from Waste Hannover GmbH and mycon’s own measurements have resulted in more than fifty thousand data records to date. On the basis of these data sets, calculation models have been developed which will lead to the creation of corresponding algorithms for different heat exchanger types / locations in the coming months. The optimum cleaning time determined can then be displayed or retrieved digitally. However, the ControlMaster measuring device can then also independently start automated cleaning processes, including all additional measures required for this. This makes considerable energy savings possible.

Heat exchangers for cooling and air conditioning account for approx. 22% of global energy consumption. There is considerable potential for savings through precise determination of the optimum cleaning time and immediate subsequent effective cleaning. mycon had already previously developed effective cleaning systems together with its sister company Kipp Umwelttechnik. Subsequently mycon developed automation possibilities for these systems.

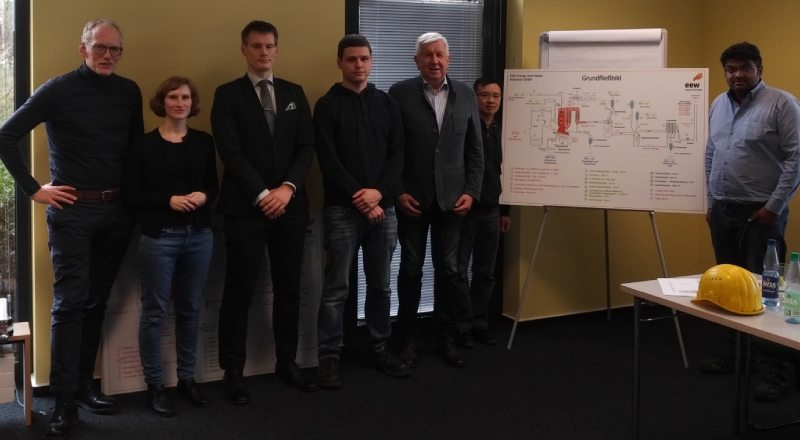

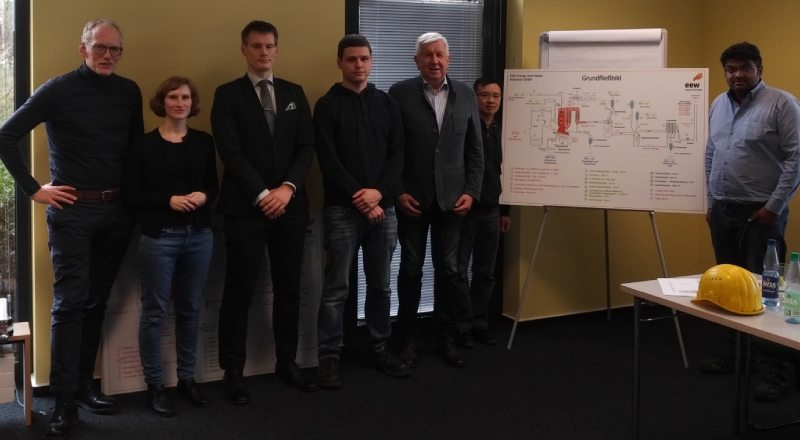

Picture: Mr. Maximilian Becker (3rd from left; Federal Office of Economic Affairs and Export Control) and the participants in the ControlMaster project (from left to right): Mr. Dipl.-Ing. Carsten Ernst (ÖkoTec Energiemanagement GmbH, Mrs. Mandy Werle (Institut für Energie- und Umweltforschung Heidelberg GmbH), Mr. Philip Modler (HAW Hamburg), Prof. Dr. -Ing. Bernd Sankol (HAW Hamburg), Mr. H.-P Nguyen (Electrical engineer mycon GmbH), Dr.-Ing. Hiren Gandhi (mycon GmbH)

ControlMaster determines the cleaning dates for the fully automatic and patented JetMaster AS cleaning system developed by mycon and installed at the customer. JetMaster AS cleans thoroughly and effectively with compressed air and only approx. 3 litres of clear water per minute.

Picture: Automated cleaning plant for air-cooled condenser (LuKo) in a waste incineration plant

Photos: mycon GmbH

Contact: Dr.-Ing. Hiren Gandhi, mycon GmbH – info@mycon.info

About mycon GmbH

mycon GmbH, a sister company of the service company Kipp Umwelttechnik, develops, manufactures and markets new products and automation technologies.

mycon GmbH currently supplies customers in approx. 40 countries.

Many years of experience in industrial service have resulted in many system developments and patents, some with international validity.